DHT-150LSA square cross flow glass fiber reinforced plastic cooling tower

Details description

Anhui Dingsheng Industrial Refrigeration Equipment Co.,Ltd.is a collection of scientific research,design,production,sales,service as one of the large enterprises.Main products include:cooling tower cooling towers||||glass fiber reinforced plastic cooling tower cooling tower high temperature cooling tower energy-saving square cross flow cooling tower cooling tower industrial cooling tower||||||circular cooling tower square countercurrent cooling tower of the central air conditioning cooling towers,and is widely used in plastics,electronics,chemical industry,chemical fiber,electroplating,food,textile,clothing,printing,blow molding,blister,medicine,fresh,architectural,mechanical equipment,and many other industries and fields.The company has many years of production experience and strong technical development ability,standardized management and good operation mechanism so that enterprises attract a large number of professionals,so as to ensure the high quality of products.And by the first-class quality and exquisite service by the customer's consistent praise,its excellent performance,reasonable price so that Dingsheng series products have been selling well at home and abroad.

Anhui golden industrial refrigeration equipment co.,LTD.,engaged in glass fiber reinforced plastic industry over the past 15 years,mainly produce square countercurrent cooling tower cooling tower square cross flow cooling tower||||||circular cooling tower water turbine cooling tower mute cooling tower closed cooling tower|||anhui cooling tower,central air conditioning cooling tower and is widely used in plastics,electronics,chemical industry,chemical fiber,electroplating,food,textile,clothing,printing,blow molding,blister,medicine,fresh,architectural,mechanical equipment,and many other industries and fields.

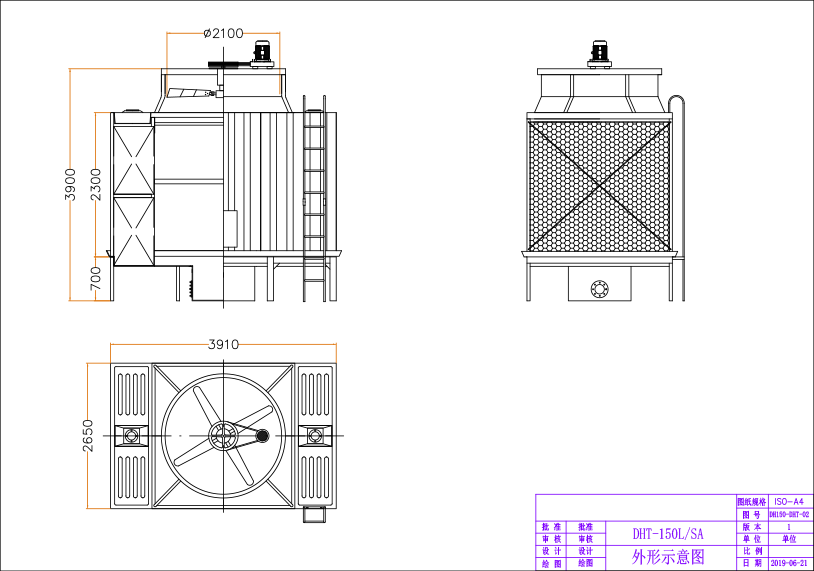

This series of cross flow FRP cooling tower adopts two sides of the inlet air,by the top of the fan,so that the air through the packing on both sides of the tower,medium exchange with hot water,the hot and humid air is discharged to the tower.The packing adopts the point wave plate with convex points on both sides,and the installation head makes the point wave plate bond into a whole to improve the rigidity.The convex points on both sides can also avoid direct drop of water,so the formation ability of water film is improved.The tail of the packing is equipped with water collecting measures.

Product Specialties:

1,save space,lightweight structure using specially designed for this series of cooling tower high efficiency heat exchange packing,the heat exchange area is greatly improved,its floor area is greatly reduced,due to the optimization of structural design and the use of steel structure,operation weight is also greatly reduced.

2,save power using small ventilation resistance packing and designed by Tsinghua University for cooling tower airfoil FRP fan,so as to reduce the power of the motor,the low noise type of motor power is smaller,more save power,but also according to the requirements of the user,with a double speed motor to save power.

3,the operation noise is very low.The FRP material of Tsinghua University is specially designed for the cooling tower,and the FRP material is specially designed for the cooling tower,and the low noise motor is specially designed for the cooling tower,so as to reduce the operation noise of the cooling tower.Low noise series cooling tower operation noise is lower,in line with environmental protection requirements.If the two-speed motor is equipped,the noise can be reduced by 2-3dB(A)when running at low speed at night.Users who need the two-speed motor should put forward separate requirements when ordering.

4,good corrosion resistance tower body,tank and panel are made of FRP material with good corrosion resistance,and in the gel coat resin with light stabilizer,has good aging resistance,durable and does not change color.The steel structure of the tower body is processed by zinc plating,which improves the corrosion resistance of the cooling tower.In the normal service life,there is no need for additional corrosion resistance.

5,convenient combination can be adopted to meet the requirements of different working conditions,the user can also decide the combination according to the site,and can adjust the appearance of the cooling tower according to the characteristics of the user's building.If the user space is very limited.Our company can also be designed according to the special requirements of users to meet the requirements of thermal performance and noise.

This series of cooling tower is a combined design,and the air chambers of adjacent cooling towers are separated from each other.Under the premise of normal operation of the cooling tower,maintenance and repair can be carried out,and the work of cleaning packing,water pipe and water tank is more convenient.

Product structure:

(1)panel:glass fiber reinforced plastic material,smooth and beautiful surface,corrosion resistance,anti aging.

(2)packing:modified polyvinyl chloride bi-directional point wave plate,good thermal performance,small airflow resistance,good rigidity,heat resistance 75℃,cold resistance,flame retardant.

(3)Fan:blade material is alloy aluminum plate.The fan has the characteristics of reasonable aerodynamic force,large air volume,high efficiency,low noise and corrosion resistance.

(4)Motor and reducer:Outsourced equipment.

(5)cloth sink:glass fiber reinforced plastic material,water distribution uniform,low noise type cover plate can cover light,prevent debris flying into,reduce splash sound.

(6)anechoic cover:glass fiber reinforced plastic material,with cavity type flame retardant PVC film anechoic material.

(7)Blind window:FRP material,can waterproof splash,and can make the air flow into the tower uniform.

(8)Water tank:made of glass fiber reinforced plastic,plays the role of collecting water,equipped with automatic water supplement facilities,can be closed circuit circulation directly absorbing water.

(9)skeleton:for the folded steel assembly structure,good rigidity,light weight,convenient transportation,installation,hot dip galvanized anticorrosion.

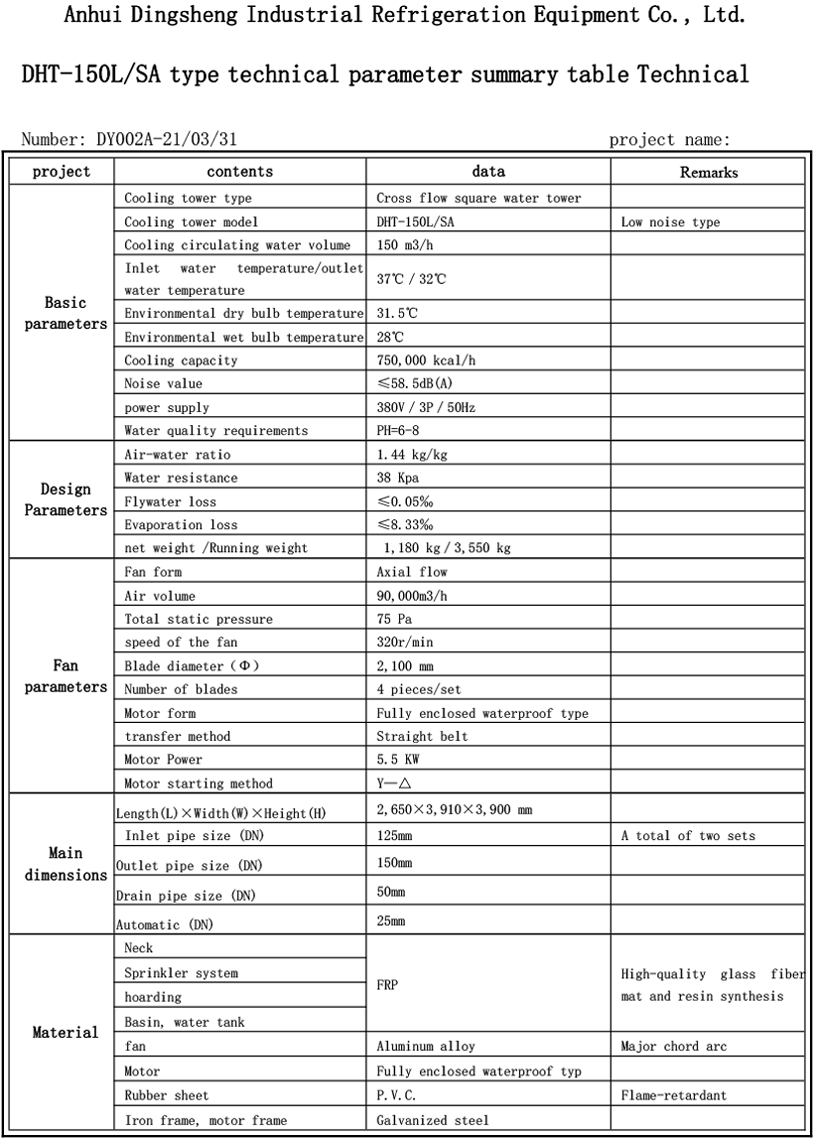

Performance and Selection

1.Design parameters:

1)standard conditions:water temperature t1=37℃,the temperature t2=32℃,design wet-bulb tau=28℃,the water temperatureΔt=5℃,cold high t2-tau=5℃

T1=2)medium temperature conditions:water temperature 43℃,the temperature t2=33℃,design wet-bulb tau=28℃,the water temperatureΔt=10℃,cold high t2-tau=6℃

T1=3)high temperature working condition,water temperature 60℃,the temperature t2=35℃,design wet-bulb tau=28℃,the water temperatureΔt=25℃,cold high t2-tau=8℃

2,the selection of instructions to know the water quantity Q,inlet temperature T1,outlet temperature T2 and design wet-bulb temperatureτ,and then according to the thermal performance to calculate.On the working conditions outside the curve table,can be thermal calculation,the volume of the packing bulk coefficientβ×νis as follows:1.2 times the nominal flow:β×ν=18600 1.0 times the nominal flow:β×ν=17800 0.8 times the nominal flow:β×ν=17000

3.The operating weight shall be calculated according to half of the water stored in the tower body.If it is filled with water,it shall be multiplied by 1.5.

4,this series of cooling tower for the average monthly temperature is not lower than-10℃area,the temperature is too low when used,should consider the pipeline and water tank icing problem,especially in the winter discontinuous operation process,the water pump directly from the circulation system in the tank of the tower,but also should be considered,avoid icing problem,if necessary,need to add electric heating pipe in the tank.

5,the applicable water temperature is 65℃,such as 65℃,when ordering should put forward the water temperature requirements,in order to consider when selecting materials,such as flame retardant or non-flammable requirements,should be based on the local fire department of FRP oxygen index requirements for production,should be put forward by the user in advance.It is recommended that the user choose flame retardant FRP for the horizontal flow tower installed on the roof.I plant production of flame retardant,flammable FRP material,its oxygen index reached≥31 or≥35 respectively.6.Turbidity of circulating water should not be greater than 50 ml/L,not more than 100 ml/L in a short term.It should not contain oil and mechanical impurities,and measures should be taken to eliminate algae and stabilize water quality when necessary.

7.The water distribution hole of the water distribution tank shall be opened according to the nominal flow rate.If the actual flow rate exceeds the nominal flow rate by 25%,it shall be explained when ordering.

8.The water pressure of the inlet pipe is about 2-5 m Hg.Do not design the pressure too high,otherwise it will produce floating water phenomenon.

9,motor,fan are supporting the supply.The factory needs to send personnel on-site installation or technical guidance,additional charge.

10.Sewage pipe,overflow pipe,automatic water supply pipe and rapid water supply pipe can be selected according to user requirements.Model code and meaning:B-FRP H-cross flow tower Z-assembled L-cooling tower D-low noise type CD-low noise type G-medium and high water temperature drop industrial type

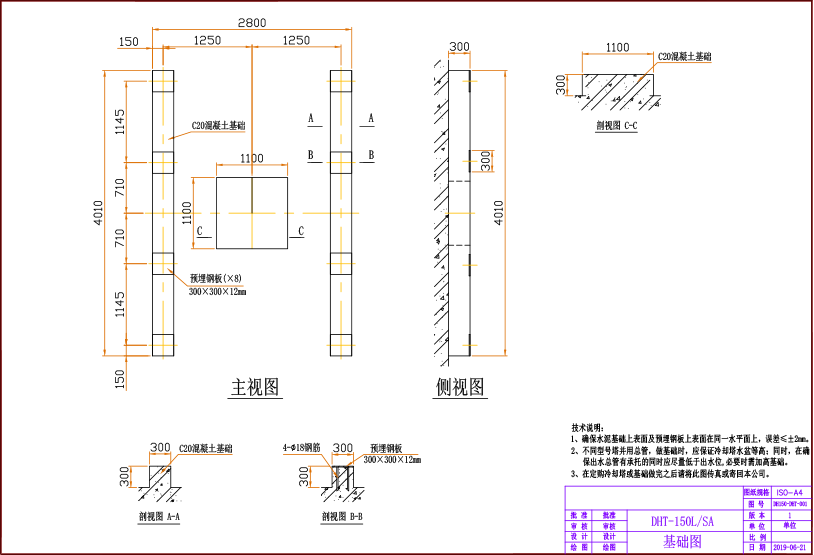

Installation and use matters needing attention

1,should be placed in a well-ventilated and clean place.

2.The inlet water pipe of the cross-flow tower is respectively installed on both sides and connected to the water distribution tank.The user should set a butterfly valve at the nozzle to adjust the flow.The intake water pipe can be led from the main pipe below,or the main pipe can be placed on the tower,in which case its pipe bracket should fall on the rack on the side of the cooling tower.The outlet pipe can be connected from the tank at the bottom of the tower in any direction of the inlet air.

3.When using,the roundness of the air duct should be adjusted,and the gap between the blade tip and the tower wall should be equal,not less than 10mm.The blade Angle should be adjusted to the same.The method of adjusting the blade is to mark the front and rear edges of each blade at 150mm close to the blade tip,and then measure the distance between the front and rear edges of each blade by the lower chord of the bracket respectively,so as to calculate the height difference of the front and rear edges of each blade.After several adjustments,it is qualified to achieve the same height difference.4,should avoid in the ash layer,acid gas field used,otherwise it will lead to heat exchanger and pipe corrosion.

5,the distance between the air inlet and the wall of the cooling tower is as follows:single tower is 2 meters,double tower is 2.5 meters,three tower is 3.5 meters,four tower should be more than 5 meters,the wall height should be lower than the overall height of the cooling tower.

6.The distance between the exhaust port of the cooling tower and the obstacle should be more than 5 meters.