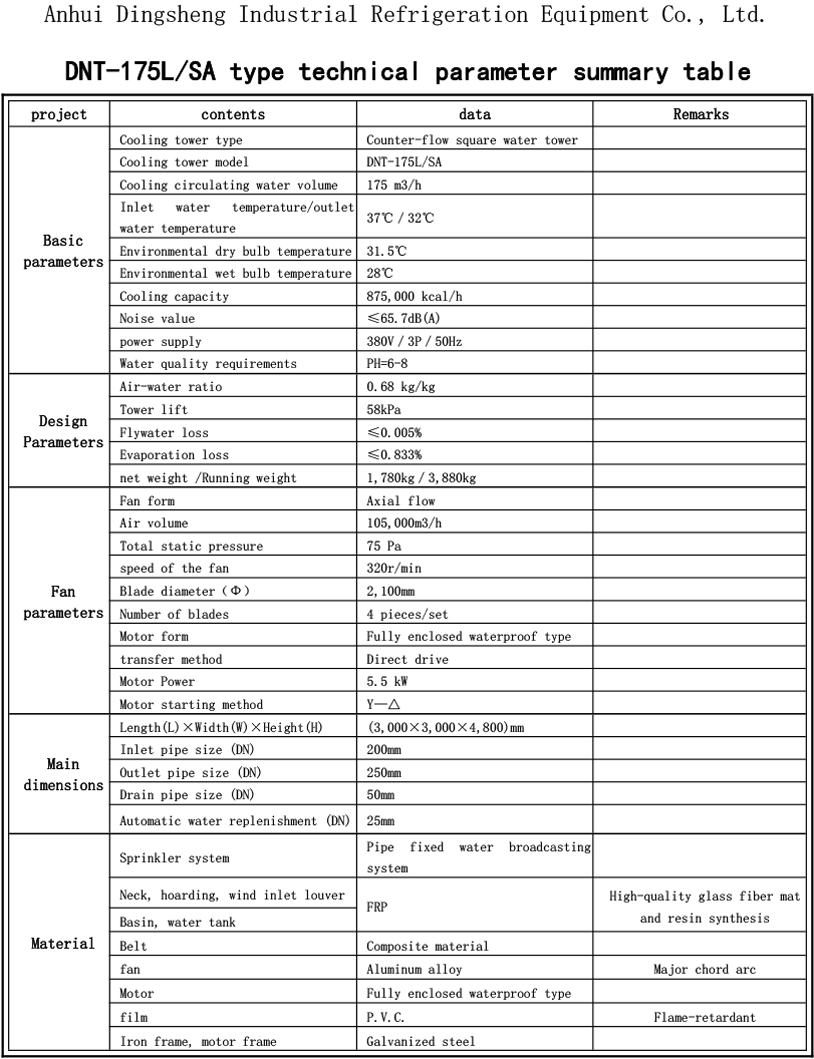

DNT-175LSA square countercurrent cooling tower

Details description

Anhui golden industrial refrigeration equipment co., LTD., engaged in glass fiber reinforced plastic industry over the past 15 years, mainly produce square countercurrent cooling tower cooling tower square cross flow cooling tower | circular cooling tower water turbine cooling tower mute cooling tower closed cooling tower | | | anhui cooling tower, central air conditioning cooling tower and is widely used in plastics, electronics, chemical industry, chemical fiber, electroplating, food, textile, clothing, printing, blow molding, blister, medicine, fresh, architectural, mechanical equipment, and many other industries and fields.

Product introduction:

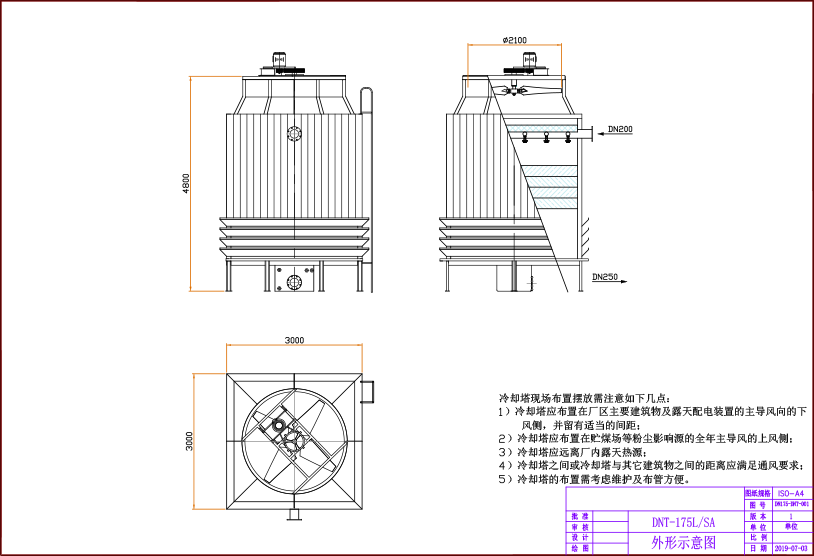

This series of square countercurrent cooling tower adopts countercurrent gas-heat exchange technology, so that the cold air enters the wind from the bottom of the cooling tower, countercurrent goes up into the packing layer, and heat exchange with heat is realized. The main body adopts all-steel structure, FRP protective plate, and the tower body is equipped with maintenance escalator for the normal maintenance and management of the tower top equipment. The use of S corrugated packing, modified PVC material, special structure of the flow film to diffuse the drench area; Through the spray pipe and sprinkler head splashing water distribution way, to achieve uniform water distribution, increase heat dissipation, enhance the cooling effect.

Our company according to nearly 20 years of manufacturing experience, the structure design of this series of products made partial improvement, so that its operation is more stable and reliable, the main body is durable, assembly is more convenient, the maintenance rate is very low. The company put an end to the "extensive" production management, the implementation of standardized production, product highly mechanized operation. Products are widely used in petroleum, chemical, smelting, rubber, food, air conditioning, injection molding, pharmaceutical, brewing and other industries of circulating water cooling process.

|

Type |

Flow |

Dimensions(mm) |

Fan diameter |

Electric power |

Water pressure (kpa) |

Running heavy |

|||

|

(m3/h) |

long(L) |

width (W) |

Height(H) |

(mm) |

(kw) |

|

net weight DRY |

Running weight WET |

|

|

DS-250T |

250 |

3500 |

3500 |

4450 |

2850 |

11 |

45 |

2150 |

5285 |

|

DS-300T |

300 |

3750 |

3750 |

4900 |

3200 |

11 |

47 |

2620 |

6050 |

|

DS-350T |

350 |

4000 |

4000 |

5000 |

3200 |

11 |

47 |

2950 |

6590 |

|

DS-400T |

400 |

4500 |

4500 |

5000 |

3400 |

15 |

48 |

3520 |

7850 |

|

DS-450T |

450 |

4800 |

4800 |

5000 |

3400 |

15 |

48 |

3810 |

8160 |

cooling tower structure:

|

heading |

directions |

|

Main steel structure |

It is made of Q235 national standard steel material (first-grade steel), and is processed by advanced good-flow line technology. It is fully mechanized and automated. The overall structure is high in strength and reasonable in structure. The tower structure has the effect of multi-directional force performance, can effectively bear concentrated load, asymmetric load, and reduce the vibration of the cooling tower. |

|

Peripheral guard plate |

Using mechanical high temperature pultruded profiles, for high strength FRP composite material, the strength is second only to steel plate. The appearance is beautiful and easy, the size is smooth. Long service life, easy to disassemble |

|

Air duct |

Made of glass fiber reinforced plastic, flame retardant oxygen index ≥40, using automatic injection technology, uniform thickness, large glue content, smooth surface, strong overall rigidity. The distance between the inner wall of the air duct and the blade tip of the fan is controlled at 30±5mm. Made of glass fiber reinforced plastic, flame retardant oxygen index ≥40, using automatic injection technology, uniform thickness, large glue content, smooth surface, strong overall rigidity. The distance between the inner wall of the air duct and the blade tip of the fan is controlled at 30±5mm. |

|

Waterproof motor |

It is a special Y series outdoor cooling tower motor which is waterproof, moisture-proof and corrosion-resistant. It has good tightness and is widely used in cooling tower environment under various conditions. The insulation grade is F, and the protection grade reaches IP55. The working voltage of the motor is 380V, and the rated frequency is 50Hz. |

|

reducer |

It is a reducer which uses the principle of planetary gear train transmission and the floating meshing mechanism of hard tooth surface cylindrical gear. The product has the advantages of compact structure, small volume, smooth operation, low noise, corrosion resistance, long service life and convenient use and maintenance. |

|

Cooling fan |

The aerofoil axial flow fan is designed for the Department of Engineering Mechanics of Tsinghua University. The blade is made of aluminum alloy. The blade adopts adjustable hub, which can be angled according to the demand conditions. Reasonable aerodynamic force, high efficiency, large air volume, low noise, corrosion resistance. The design service life is 15 years. |

|

Water distribution system and nozzle |

Adopt pipe type water distribution system, water distribution system has anti-blocking performance. The distribution flow deviation of sprinkler heads at different positions in the tower is less than 5%, and the water distribution system is uniform within 70% ~ 130% of the rated flow. The nozzle material is ABS engineering plastic, injection molding, using wide Angle design, uniform atomization, no dead Angle. Ensure the water temperature reaches 80℃. |

|

Thermal filler |

Packing is an important part of cooling tower, its efficiency depends on the full contact degree of cooling water and air in the packing. Our company uses multi-corrugated S type packing, size: 1000mm×500mm×0.4mm. Unique packing flow channel, so that the water flow on the packing surface can form a large area of flowing water film, prolong the cooling time of water in the packing, so that the air can quickly take away the heat in the water, improve the water cooling effect. The material is a new modified PVC material with a temperature resistance of 60℃. |

|

Water collector |

Recycling-type dewatering device adopts corrosion-resistant PVC material, its structure by changing the flow direction, can effectively remove from the packing out of the wet air moisture, so that the water flow rate is reduced to 0.001% below. When cleaning the packing, the water separator can be easily removed. |

|

Ladder, guardrail |

The cooling tower is installed with ladder and guardrail, which is convenient for daily inspection and maintenance. |

Motor insulation class

Performance reference temperature (℃)

Insulation temperature class

Rank A

Rank E

Rank B

Rank F

Rank H

Allowable temperature(℃)

105

120

130

155

180

Winding temperature rise limit (K)

60

75

80

100

125

80

95

100

120

145

The motor protection grade reaches IP55

IP(Ingress Protection)PROTECTION level system is drafted by the IEC(International Electrotechnical Commission).Electrical appliances are classified according to their dust-proof and moisture-proof properties.IP protection grade is composed of two numbers,the first number represents the lamp from the dust,to prevent the invasion of foreign objects,the second number represents the lamp against moisture,waterproof invasion of the airtight degree,the greater the number means that the protection grade is higher.

Meaning of the first number:

0:No protection,no special protection

1:the protection of more than 50mm of solid,can prevent the diameter of more than 50mm of solid foreign bodies into the shell.It prevents a large part of the human body(such as the hand)from accidentally or accidentally touching the live or moving parts of the shell,but does not prevent conscious access to these parts

2:the protection of more than 12mm of solid,can prevent the diameter of more than 12mm of solid foreign bodies into the shell.It can prevent fingers from touching the charged or moving part of the shell

3:the protection of more than 2.5mm of solid,can prevent the diameter of more than 2.5mm of solid foreign bodies into the shell.It can prevent tools and metal wires with thickness or diameter greater than 2.5mm from touching the live or moving parts in the shell①②

4:the protection of more than 1mm of solid,can prevent the diameter of more than 1mm of solid foreign bodies into the shell.The wire or strip with diameter or thickness greater than 1mm can be prevented from touching the live or running part of the shell①②

5:Dustproof,can prevent dust from entering to the extent of affecting the normal operation of the product,completely prevent touching the live or moving part of the shell.

6:Dust dense,can completely prevent dust into the shell,completely prevent touching the charged or moving part of the shell

Meaning of the second number:

0:No protection,no special protection

1:anti-drip,vertical water should not be directly into the motor

2:15o anti-drip,and plumb line into a 15o Angle range of water drop,should not directly into the motor inside

3:waterproof water,and the plumb line into a 60O Angle range of water,should not be directly into the motor

4:anti-splash,any direction of splashing water should have no harmful effect on the motor

5:Water spray,any direction of the water should have no harmful effect on the motor

6:anti-wave or imposed spray,violent waves or strong spray should have no harmful effect on the motor

7:immersed in water,the motor is immersed in water under the specified pressure and time,and the amount of water should have no harmful effect

8:diving,the motor is immersed in water for a long time under the specified pressure,the amount of water should have no harmful effect

The protection level commonly used in motor application is IP11,IP21,IP22,IP23,IP44,IP54,IP55 and so on.